How to construct a house with low cost in India

The structure or redesigning a house is a costly recommendation as each easily overlooked detail adds up, regardless of whether it’s the material or work costs. It pays to have a reasonable thought of what you need to accomplish with the goal that your financial plan isn’t squandered on re-trying components. Reusing old material or deciding on D-I-Y highlights is one more method for keeping the expenses as low as could really be expected.

10 tips in this blog to assist you with building your home low cost in India.

- Brick work furniture

- Concrete ground surface

- Dividers with concrete

- Beds for dividers

- Uncovered block finish

- Reused wood

- Substantial squares

- Noticeable lines and installations

- Reuse and old items

- Use AAC Blocks

1. Brick work furniture

Regardless of whether you need to assemble a bar counter inside or fixed seating outside, workmanship furniture that utilizes blocks, stone, or concrete as a base isn’t just prudent yet in addition tough. It’s particularly really smart for the outside where the furniture is presented to normal components. use bricks ppc cement like ambuja, ultartech, jk, shree etc.

2. Concrete ground surface

Rather than stone or fired tiles, consider utilizing concrete deck to minimize expenses. It’s not difficult to keep up with and is an ideal choice for a natural home. Other than being not difficult to introduce, a substantial floor can likewise be enlivened with mosaic tile borders or a layer of paint to light up the home.

3. Dividers with concrete

Cement can likewise be utilized on dividers to give a room an advanced modern look. It’s a reasonable choice contrasted with earthenware tiles and is without upkeep as well. try to best cement in home because top cement give you high coverage area .you will choice ambuja cement. ultartech cement, jk cement ,or shree cement etc.

4. Beds for dividers

As of late, wooden beds have acquired ubiquity as an eco-accommodating option in contrast to customary wood cladding on dividers. Other than being practical for a low-spending plan house, they accompany the upside of matching work of art and contemporary homes the same.

5. Uncovered block finish

As well as adding warmth to the home’s atmosphere, uncovered block gets rid of the expense of putting and painting the dividers. This is likewise a choice while remodeling as you can eliminate the mortar and paint to give your home a natural vibe utilizing the open-block treatment on the dividers.

6. Reused wood

Wood is an optimal material to use for building rooftops over the porch or as deck flooring in the outside on the grounds that it adds to the normal style of the plan. Rather than utilizing new wood, you can reuse old boards and shafts to bring down costs. Since it’s a simple material to work with, assuming you have what it takes for it, you might select D-I-Y projects with wood to limit costs.

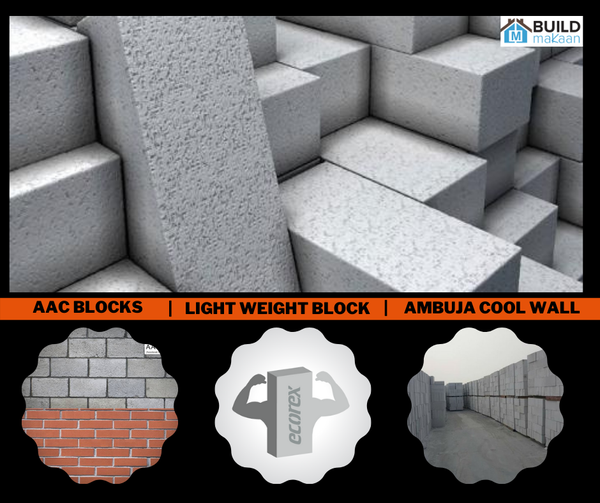

7. Substantial squares

You can assemble your home Lego-style, utilizing readymade substantial squares. They are a minimal expense elective and are home easy to build with.

8. Noticeable lines and installations

Uncovered lines and apparatuses are a typical element of the cutting edge modern house plan. Notwithstanding, they are utilitarian too as it’s not difficult to recognize and fix holes or line explodes. Also, you save money on the costs associated with putting to cover them.

9. Reuse and old items

Regardless of whether it’s your furnishings, decorations, or stylistic theme embellishments, you can make a critical saving by reusing. Convert beds or old wood into a couch casing or end table. Hit carport deals or secondhand store to observe adornments that go with the style of your home.

Follow these tips to fabricate a beguiling home on a careful spending plan. See this manual for a few wonderful homes that were constructed modest.

10. Use AAC Blocks

By picking eco-accommodating development materials for building your fantasy home, you are not simply doing your piece to ration the climate yet additionally saving money on your general development costs. Among the inventive development materials utilized across the world, autoclaved circulated air through substantial squares (AAC squares or blocks) are viewed as better than other traditional materials like consumed mud blocks that cause ecological perils. The advantages of AAC blocks as a reasonable and practical option in contrast to conventional structure materials are as a rule generally perceived in India. In this article, we clarify AAC blocks and their benefits and detriments in house development.

Some more home financial plan tips

For quite a long time bamboo has been utilized for executing low-financial plan house designs, and even today, it is generally liked by a lot of people. It is very normal to observe inside originators involving bamboo for the roof and railing as it is powerful, sturdy, and simple to work with. Other than the roof, it can likewise be utilized as a ground surface or roofing material. Above all, not at all like other structure materials, bamboo represents no risk to wellbeing.

For minimal expense house plans with gauges inside a little financial plan, experts regularly think about overlay as an incredible decision with regards to deck. Other than being cheap, it is not difficult to keep up with and can act better than stone when a virus feeling isn’t favored underneath. What’s more, overlay is impervious to stains and scratches; be that as it may, the creases between the boards are inclined to water harm. Most importantly, its fine surface adds the necessary measure of warmth and improves the magnificence of homes that have a provincial setting